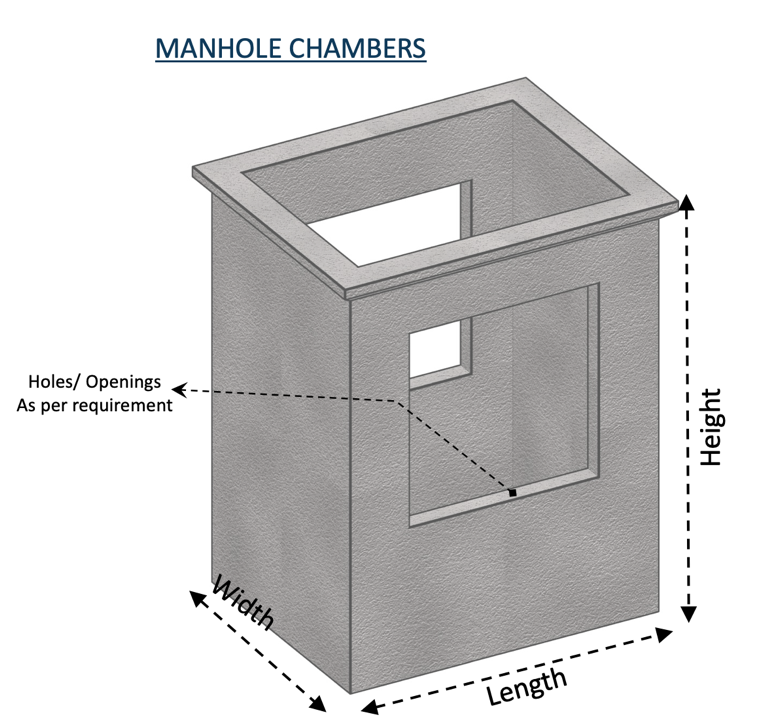

Manhole Chambers / Utility Chambers

TVK’s Precast Manhole Chambers are cast monolithically on precision moulds, ensuring watertight performance and high durability. Available sizes range from 600×600 mm to 1500×1500 mm. Covers are supplied as per load requirements.

Purpose of Precast Manhole Chamber

- 🔧 Inspection, cleaning, and removal of obstructions in sewer/water lines.

- 🔄 Joining or changing direction/alignment of sewer or water pipes.

- 🌬️ Ventilation via perforated cover to allow escape of gases.

Conventional Construction Challenges

Construction of chambers below ground level in conventional method is a very tedious activity, as the size of the chambers are very narrow and provide very little working space. Moreover, sealing the construction joints against water leaks is highly challenging, resulting in poor durability and maintenance issues over time.

Material Specification

- Concrete: Grade 40 – 45

- Steel: Fe500

- Nominal Cover: 25 mm

Requirements

- Backfill soil density ≥ 18 kN/m³.

- Granular backfill adjacent to side walls.

- Layer-by-layer uniform compaction around chamber.

Design Criteria

- BS 5400 : Part 4 : 1990 | BD 31/01 | MS 1293 : Part 1 : 1992

- IRC 6 – 2000 Cl 214.1.1.3 | IS 456 : 2000 | IS 12592 : 2002

Construction Overview

Chambers are monolithically cast up to 2 m depth. For deeper chambers, joints are formed at 2 m intervals, sealed with polyurethane sealant. This system eliminates leakage risks, speeds up installation, and ensures long-term integrity.

Advantages over Conventional In-Situ Manholes

Robust Design

Engineered for superior durability and long-term structural strength.

High Quality Finish

Consistent production using high-quality materials and precise moulds.

Long Service Life

Designed for decades of service with minimal degradation over time.

Maintenance-Free

No recurring maintenance — saves operational time and cost.

Safe & Fast Installation

Safer, quicker, and more cost-efficient compared to conventional builds.

Watertight

Monolithic casting ensures perfect sealing and zero leakage.

Eco-Friendly

Less waste on site with a reduced carbon footprint during construction.

Minimal Site Work

Precast design reduces onsite activities and mess significantly.

Predefined Openings

Openings for service line connections are pre-provided in factory.

Versatile Connections

Supports all standard pipe materials, diameters, and orientations.

Retrofittable Design

Can be modified for future developments without replacement.

Cost & Time Savings

Reduces total project duration and overall construction expenses.

Realtime Images