CUSTOM FACTORY ASSEMBLED TANKS

The term "custom" implies that these tanks are tailored to the unique needs of a particular project or client. Custom factory-assembled tanks are manufactured off-site in our Precast Factory and transported to the installation site as fully assembled units. These tanks are designed for water storage, wastewater treatment, chemical storage, and more.

ADVANTAGE - CUSTOM FACTORY ASSEMBLED TANKS

CUSTOM DESIGN

Available in various shapes, sizes, and configurations to meet the specific client needs and site constraints.

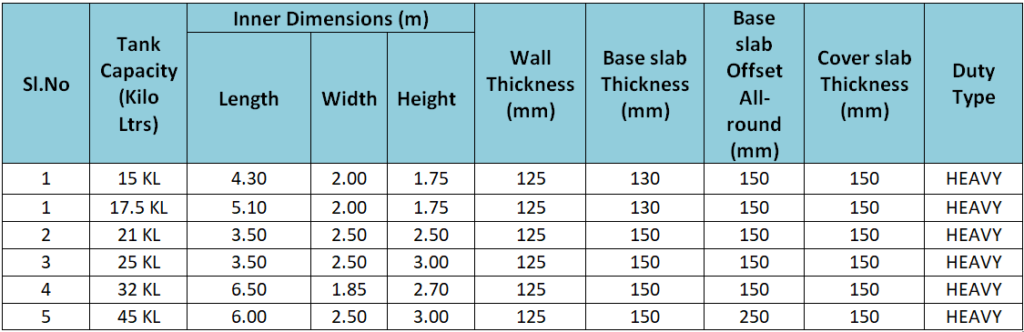

DESIGN CONSIDERATIONS

Includes capacity, dimensions, materials, and other special features designed per client requirement.

STRUCTURAL QUALITY

Walls and slabs are cast in factory with high-grade concrete and steel, ensuring durability and strength.

POST TENSIONED WALLS

Walls are connected using post-tensioning methods for robust structural integrity and leak-proof performance.

WATERPROOFING

Comprehensive waterproofing during casting to ensure long-term leak resistance and performance.

FACTORY QUALITY CONTROL

Manufactured in a controlled environment under stringent quality checks to meet all standards.

FAST INSTALLATION

Fully assembled tanks are transported to site, reducing on-site work and ensuring faster project completion.

EASY INTEGRATION

Quickly connects to existing foundations, plumbing, or monitoring systems with minimal on-site effort.

CUSTOM FEATURES

Options include access hatches, inlet/outlet fittings, and protective coatings as per client preference.

CODE COMPLIANCE

Manufactured in line with industry standards, safety norms, and regulatory requirements.

COST EFFECTIVE

Though having slightly higher initial costs, reduced site work and maintenance ensure long-term savings.

SUITABLE APPLICATIONS

Ideal for water storage, industrial use, chemical containment, and wastewater treatment.